Sustainability – in every respect

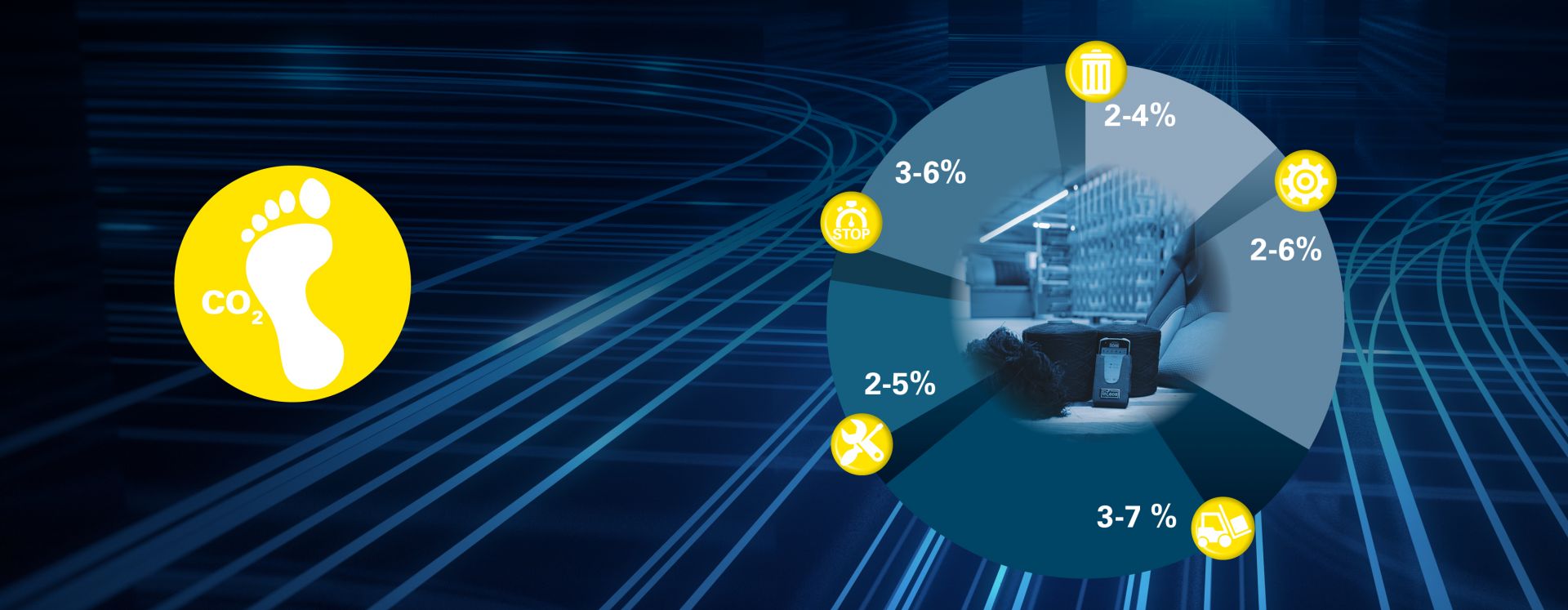

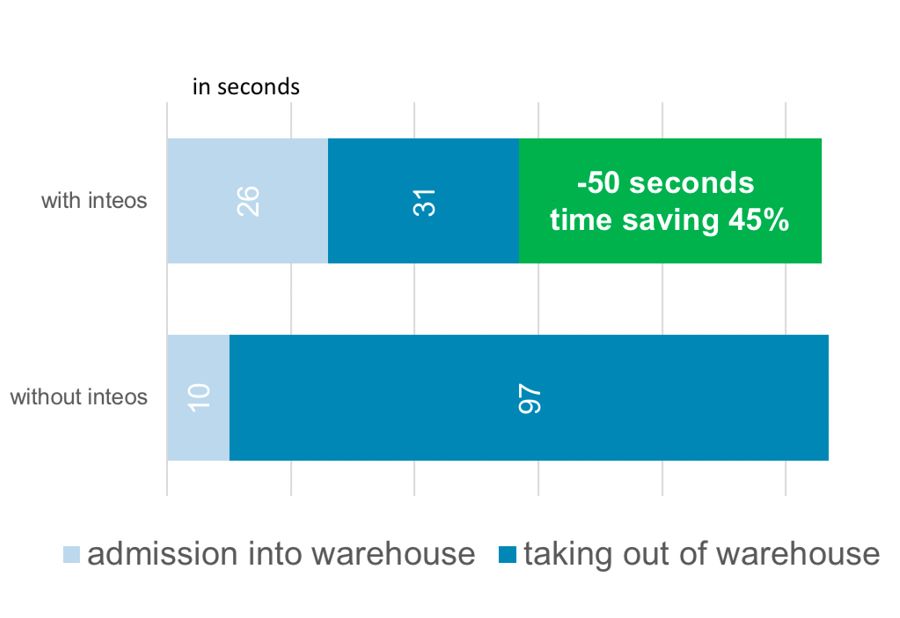

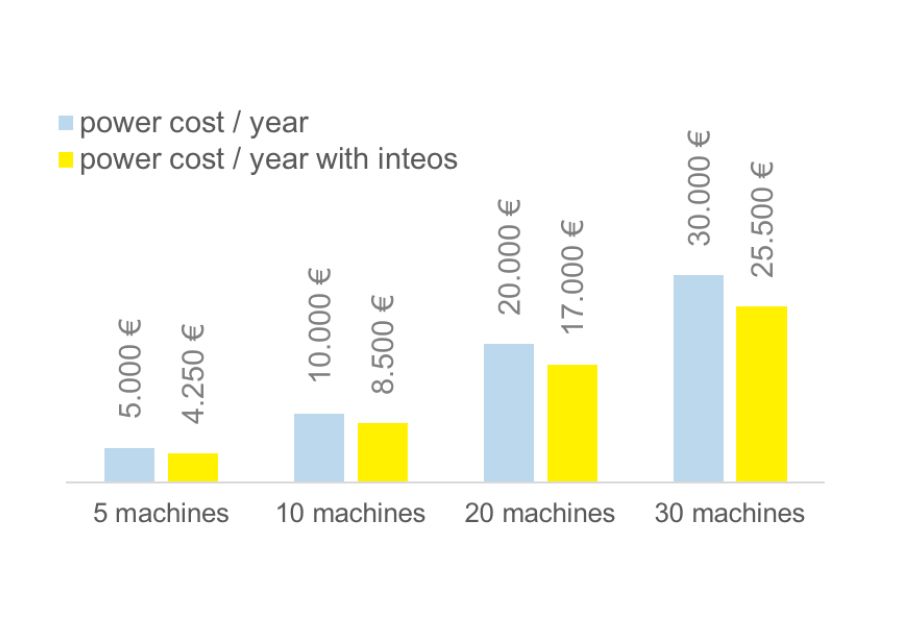

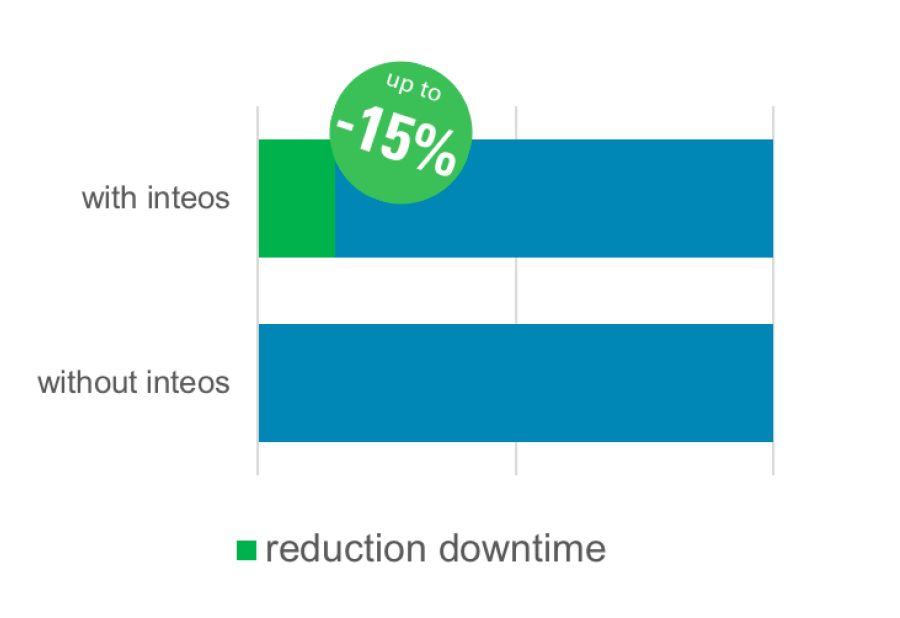

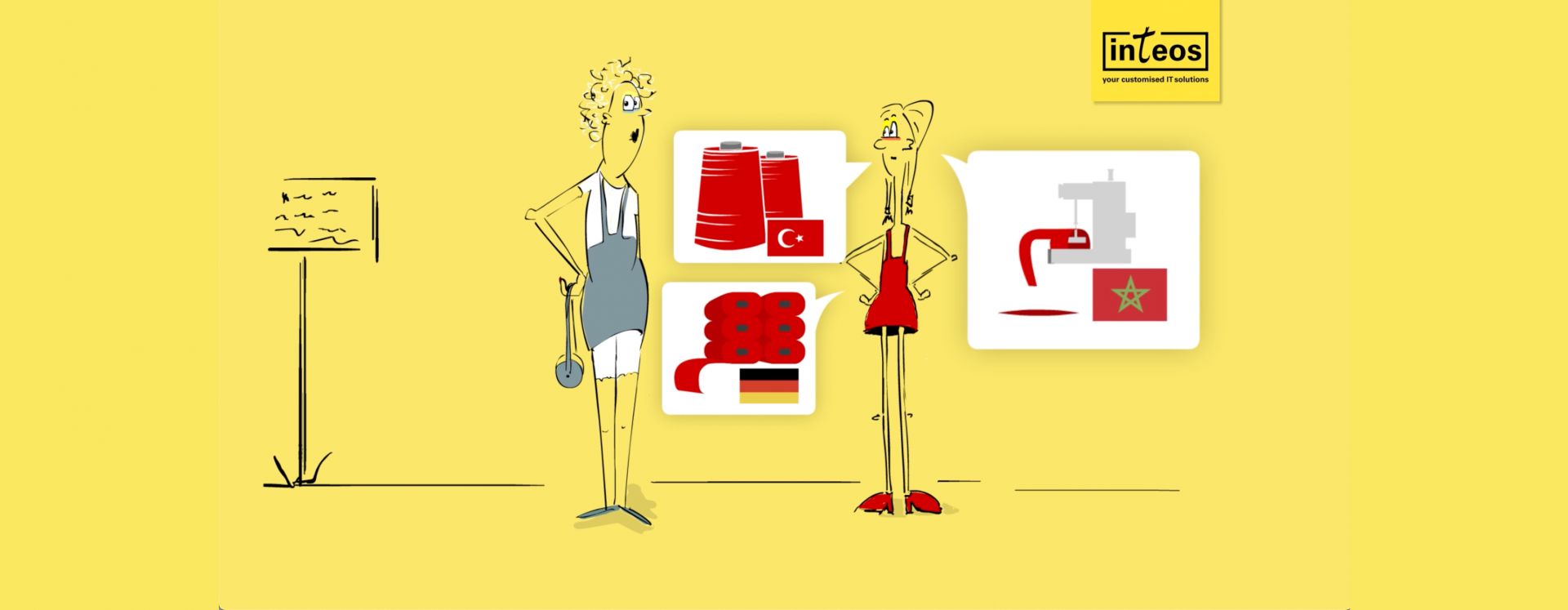

With inteos® you go for sustainability – in every respect. We understand economic and ecological sustainability as essentially interlinked processes. The more efficiently you design your internal processes, the less time, money and manpower is invested, the less resources are wasted.

With inteos® you increase the transparency of your company processes, optimize machine utilization and inventory levels and thus maximize your productivity and minimize costs and resource use. Not only is your company balance sheet happy - the ecological one will also thank you.